In today’s industrial landscape, safety is not just a priority—it’s a duty. From sprawling oil pipelines to delicate aerospace components, the integrity of materials and structures directly impacts human lives, environmental health, and economic performance. Nondestructive Testing (NDT) has emerged as a critical practice for ensuring safety without disrupting operations. What follows is an exploration of why NDT is so vital in applications that span various industries.

What is Nondestructive Testing (NDT)?

Nondestructive Testing is a term that denotes a collection of inspection techniques used to evaluate materials, components, or systems for defects—without causing damage. Unlike destructive testing, which requires sacrificing a sample or part, NDT allows for thorough analysis while leaving assets intact.

Popular NDT methods include:

- Ultrasonic Testing (UT): Detects internal flaws with high-frequency sound waves.

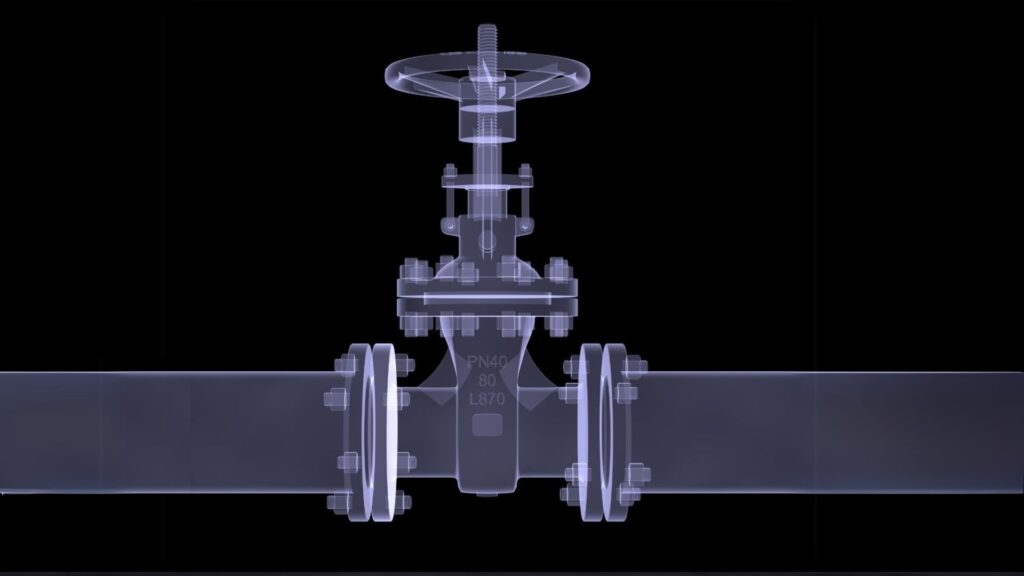

- Radiographic Testing (RT): Uses X-rays or gamma rays to reveal hidden defects.

- Magnetic Particle Testing (MT): Identifies surface and near-surface flaws in ferromagnetic materials.

- Liquid Penetrant Testing (PT): Highlights surface cracks and imperfections.

- Visual Testing (VT): The simplest yet most widely used inspection method.

Why NDT is Crucial for Industrial Safety

NDT enables industries to spot potential problems early, preventing failures that could result in injuries, environmental damage, and costly delays and repairs. Adherence to compliance standards and technician training are equally vital to ensure NDT is performed correctly and consistently.

Compliance Beyond SNT-TC-1A Standards

While the ASNT SNT-TC-1A standard has been widely used as a framework for NDT personnel certification, many industry leaders are moving toward programs that exceed these minimum requirements. Greater emphasis on compliance with internationally recognized standards such as ISO 9712 or employer-based certification programs with stricter oversight helps ensure a higher level of quality and safety. Some organizations, like IIA Field Services, are realizing that simply meeting SNT-TC-1A is not enough; achieving excellence in NDT requires going beyond baseline requirements.

Advanced Technician Training

At IIA Field Services, we believe well-trained technicians are the foundation of reliable NDT. We are increasingly prioritizing robust training programs that emphasize both technical skill and critical thinking. These programs often include advanced simulation tools, mentorship, and rigorous practical examinations. By investing in training that supersedes basic requirements, we can mitigate risks and improve confidence in our inspection results.

NDT in Action Across Industries

- Oil and Gas Industry

Pipelines, storage tanks, and offshore platforms operate under extreme pressures and temperatures. Techniques like ultrasonic and radiographic testing detect corrosion, cracks, and weld defects, preventing hazardous leaks and explosions. Regular NDT inspections performed by highly qualified technicians help companies comply with strict safety regulations and environmental standards. - Aerospace Industry

In aerospace, even minor material flaws can have catastrophic consequences. Radiographic testing ensures composites are free from voids and inclusions. Advanced compliance and technician competency are essential in this sector where lives depend on inspection accuracy. - Power Generation Sector

Nuclear and traditional power plants rely on NDT to monitor critical components like reactor vessels and steam generators. Detecting stress corrosion cracking early prevents radiation leaks and plant shutdowns. For renewable energy, NDT techniques are employed to inspect wind turbine blades and towers to ensure continued safe operation. - Manufacturing and Construction

In manufacturing, NDT ensures the quality of welds, castings, and forged parts. Magnetic particle and dye penetrant testing identify surface flaws in critical components. Construction industries use NDT to monitor the integrity of bridges, steel frameworks, and concrete structures, preventing failures that could endanger lives.

The Benefits of NDT

- Prevents Accidents: Detects defects before they lead to catastrophic failures.

- Saves Costs: Avoids expensive repairs and unplanned downtime.

- Extends Equipment Life: Supports predictive maintenance strategies.

- Ensures Compliance: Meets and exceeds industry standards and safety regulations.

Nondestructive Testing is more than a technical inspection—it’s a life-saving practice that protects people, the environment, and assets. Across oilfields, factory floors, and the skies above, NDT remains a cornerstone of industrial safety. To truly harness its power, industries must pair advanced technology with rigorous compliance and trained technicians whose credentials exceed SNT-TC-1A standards. As industries innovate and grow, NDT will continue to bridge the gap between operational efficiency and protection.