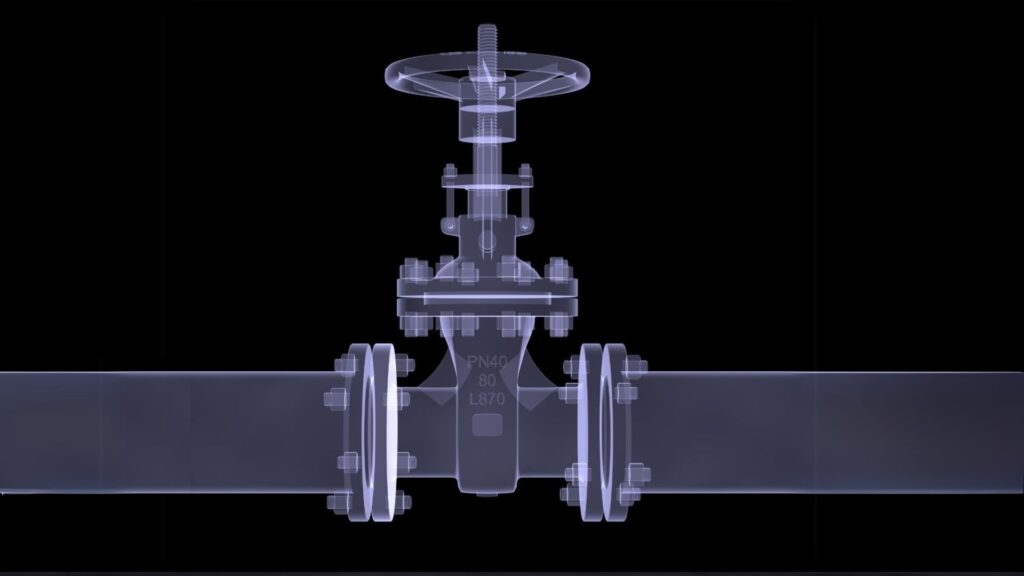

Radiographic Testing, a non-destructive testing method used to inspect the internal structure of welds and other components, involves the use of gamma rays to create images (radiographs) of the inspected object. These radiographs reveal any defects or imperfections within the material. Such defects can include cracks, porosity, slag inclusions, incomplete penetration, and more. Timely identification (and mitigation) of these flaws does much to head off bigger issues down the line.

In addition to gamma ray radiography, IIA Field Services can perform X-ray testing using an internal pipe crawler should your particular project call for it.

At IIA Field Services, we have a team of AWS Certified Welding Inspectors on staff. We are here to meet your CWI Services needs from Visual Inspection to Welder Testing. We also offer Procedure creation and qualification services. Our team is trained, certified and knowledgeable in in the standards and procedures established by The American Society of Mechanical Engineers (ASME), The American Petroleum Institute (API) and The American Welding Society (AWS).

At IIA Field Services, we specialize in providing comprehensive magnetic particle testing (MT) solutions for ensuring the integrity and safety of welds across various industries. With our advanced techniques and experienced technicians, we offer unparalleled accuracy and reliability in detecting flaws and defects in welded components.

Dye Penetrant testing is a non-destructive inspection method used to detect defects in welds or castings. It works by applying a special liquid that seeps into any cracks or flaws. After the liquid is wiped away, a contrasting developing agent is applied. Any hidden defects become visible, helping ensure the integrity of critical equipment and structures.

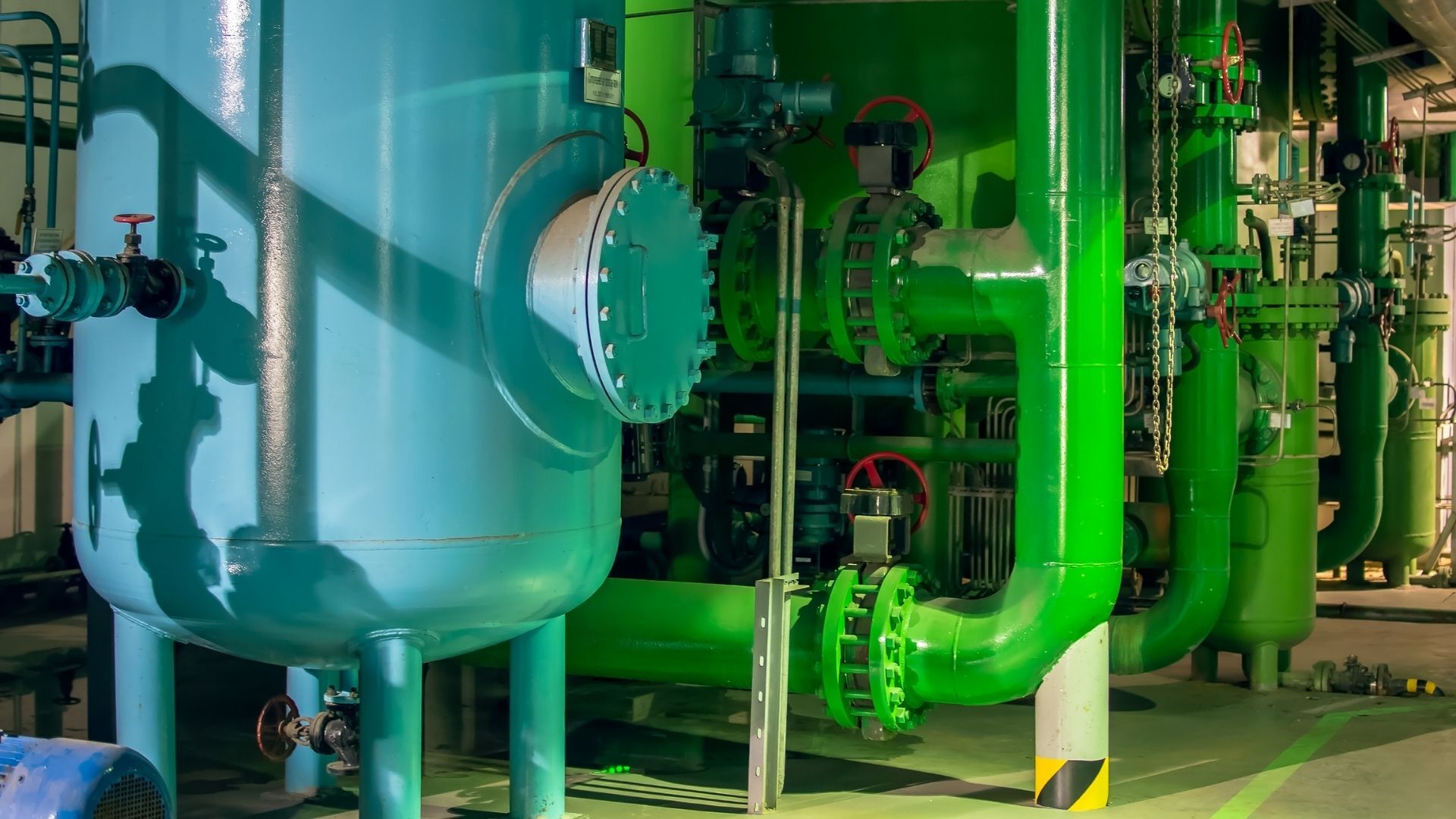

Ultrasonic thickness testing (UTT) is a non-destructive testing technique used to assess the integrity of critical infrastructure components such as pipelines, storage tanks, and pressure vessels. This method involves sending high-frequency sound waves into the material being inspected.