The leading trade publication covering the Permian Basin oil and gas industry gave some ink to IIA Field Services in their April issue, in an article entitled, “Weld Inspections: It’s a Thing.”

The coverage was part of a larger focus that the magazine, Permian Basin Oil and Gas, brought to the oilfield welding trade in general.

The IIAFS article marked the first time the 20-year-old magazine had ever covered the business of weld inspections.

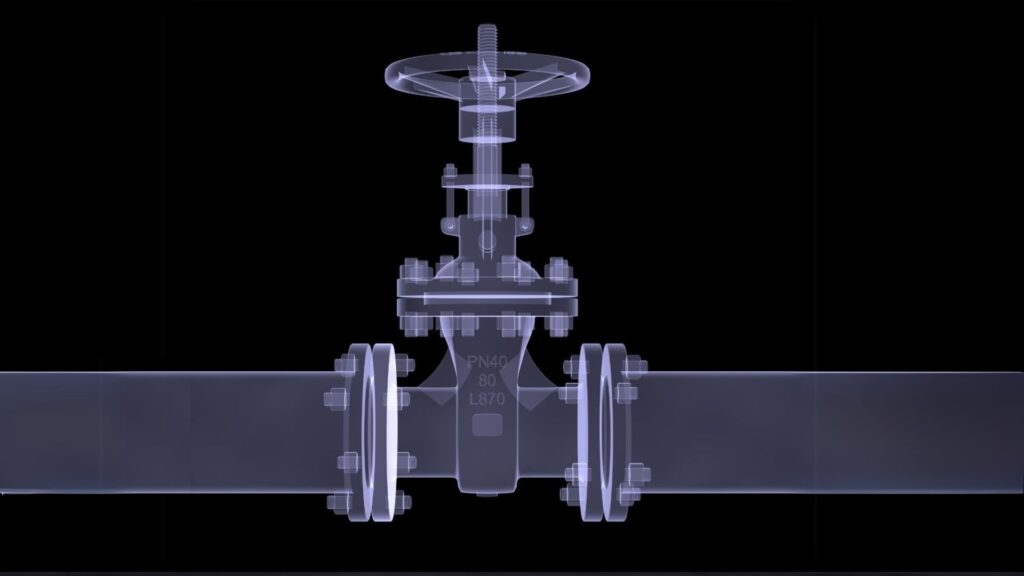

The article stated: “Among the ancillary businesses that have thrived in midstream work, we must include the lesser-known, but important, field of welding inspections. That pipe is not going to be buried until those welds are inspected and approved.”

Going further, the article acknowledged that the main players in the welding inspection niche are themselves somewhat diversified:

“Take for instance IIA Field Services. They test welds, for sure, but they do much more.”

“IIAFS General Manager Zach Bailey says they have a team of AWS (American Welding Society) Certified Welding Inspectors on staff. ‘We do everything from visual inspection to welder testing,” Bailey says. “Our team is certified in the standards and procedures established by The American Society of Mechanical Engineers (ASME), The American Petroleum Institute (API), and The American Welding Society (AWS).’ ”

Citing such services as radiographic testing (RT), X-ray testing, magnetic particle testing, dye penetrant testing, and ultrasonic testing, as well as testing the skills of a business’s welders, the magazine confirmed how IIAFS and other weld inspection companies do much more than the most simple visual inspections of welds. Theirs is a highly technical field, calling for diverse skill sets, and companies like IIAFS thrive by offering a broad suite of specialties.

The article shared Bailey’s recommendation that companies in the oil and gas field that employ welding in the oilfield should have a specific procedure.

Sounds good, but how does a company put itself on that footing?

Bailey explains:

“The CWIs here can help by writing/creating those procedures. We can create all the parameters that the welders must follow. This is called a WPS (Written Procedure Specification). All the specifications of the company’s welds are included in the WPS. Then, the procedure must be qualified. A welder must perform the welding following the specifications of the WPS and a series of testing is performed on this weld, including tensile tests, hardness tests, and toughness tests. All of the welding specifics and testing results are combined to create the Procedure Qualification Record (PQR).”

As the article showed, there is yet more to be considered. The magazine quoted Bailey on how this is done:

“’Now that we have a Written Procedure (WPS) and the Procedure has been qualified (PQR), we must test the welders,’ says Bailey, whose company does a lot of work in this vein. ‘Our team of CWI’s can come to you with all the required equipment to perform the testing. We verify all welders are welding within the WPS parameters. All welders that pass the testing will receive their Welder Performance Qualification Record (WPQR) or certification papers. This ensures that all welders welding on each project know the requirements and also that they have the skillset to perform the welds.’”

Here are some other quotes from the article:

“Business is good. We are hiring. It seems like more people are discovering us every month.” —Zach Bailey

“While headquartered in Abilene, Texas, IIA Field Services maintains Midland and Carlsbad locations, and it is in the Permian that the company is most active. ‘A lot of what we do in the Permian is pipelines,’ Bailey says.”

“Our team has the flexibility to test welders in groups of up to 20 down to a single welder in a day. We typically see a large group or groups at the beginning of a project, and then smaller groups as additional welders are added.” —Bailey

The article can be found online at this link: Weld Inspections: It’s a Thing.